Main Participants: ZHAO Weiquan, ZHANG Jinjie, ZHOU Jianhua, WANG Wenzhao, LI Yonghui, TIAN Gensheng, WANG Xinchun, ZHAO Lei

1.1 Background

Epoxy grouting materials are characterized by low viscosity, excellent groutability, high mechanical strength of the solidified mass, and strong adhesive properties. They can be used for both seepage prevention and structural reinforcement, thus being widely applied in fields such as water, hydropower and transportation. Currently, most epoxy grouts use furfural-acetone as the diluent, which can reduce the viscosity of the epoxy while maintaining excellent mechanical properties. However, furfural is highly toxic, volatile, and strongly irritant, classified as a Group 3 carcinogen. The commonly used curing agents are also low toxic, threatening human health and the environment. As a result, its application is increasingly restricted, and alternative eco-friendly epoxy grouting materials are much needed.

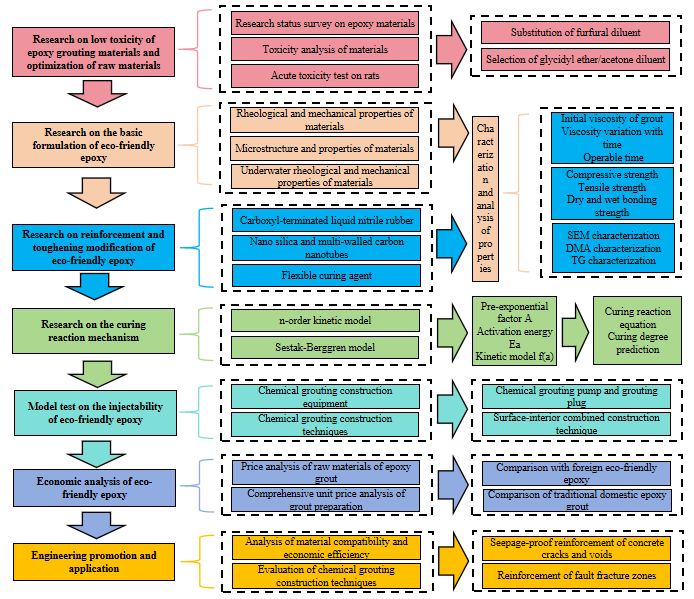

· Research on low toxicity of epoxy grouting materials and optimal selection of raw materials

· Experimental study on the basic formulation of eco-friendly epoxy grouting materials

· Research on reinforcement and toughening modification of eco-friendly epoxy

· Research on the curing reaction mechanism of epoxy grouting materials

· Simulation test on the groutability of eco-friendly epoxy

· Research on grouting construction techniques

· Engineering promotion and application

· Adopting glycidyl ether-acetone as the diluent and modified amine as the curing agent, the eco-friendly epoxy grouting formulations have been developed for various working conditions, including ordinary type, quick-setting type, high-permeability type, high-elasticity type, low-temperature type, and underwater type.

· These formulations, both in its slurry and gel states, have achieved a non-toxic level (LD50 > 5000mg/kg), and cost only 1/3 to 1/2 of imported products.

· A surface-interior combined construction technique has been developed for concrete crack treatment. The surface is coated with quick-setting epoxy for rapid sealing, while the interior of the cracks is drilled and filled with epoxy. This technique significantly improves construction efficiency and the engineering performance.

· The curing reaction process of eco-friendly epoxy has been studied using the non-isothermal DSC method. A curing mechanism model has been established to simulate the curing reaction process of the grouting material and predict the curing reaction degree.

The research achievements have been successfully applied to defect repairs in more than 10 projects, including leakage treatment in the well chamber of the South-to-North Water Diversion Project East Main Canal in Beijing, seepage treatment in the lining of headrace tunnel of the Zhelin Hydropower Plant, leakage treatment in the gallery cracks of the Hohhot Pumped Storage Hydropower Station, separation treatment in the tailwater cone pipe of the Wanjiakouzi Hydropower Station, and foundation reinforcement of wind turbines in the Huade Wind Power Plant. All these repair have achieved excellent results, demonstrating significant economic, social, ecological and environmental benefits of the eco-friendly epoxy materials and their supporting techniques.

Figure 1 Technical Route for the Research and Development of Eco-friendly Epoxy Grouting Materials

|

Type |

Ordinary type |

Quick-setting type |

High-permeability type |

High-elasticity type |

Low-temperature type |

Underwater type |

||

|

Component A |

Epoxy resin |

100 |

100 |

100 |

100 |

100 |

100 |

|

|

Diluent |

RDDF 20~30 Acetone 40~70 |

RDTF 10-20 Acetone 10~30 |

RDDF 10~30 Acetone 40~80 |

RDDF or RDTF 10~30 Acetone 10~30 |

RDDF 10~30 Acetone 40~70 |

RDDF 10~20 Acetone 10~30 |

||

|

Nano fillers |

/ |

Nano silica or multi-walled carbon nanotubes 1.0~2.0 |

/ |

Nano silica or multi-walled carbon nanotubes 1.0~2.0 |

/ |

/ |

||

|

Component B |

25~40 |

(Flexible curing agent) 35~50 |

20-30 |

(Flexible curing agent) 35~50 |

(Low-temperature curing agent) 25~40 |

(Underwater curing agent) 30~50 |

||

|

Gelation time (min) |

>30 |

10~60 |

>30 |

30~80 |

>30 |

10~60 |

||

|

Grout viscosity (mPa·s) |

20~40 |

500~1200 |

<10 |

500~1200 |

20~40 |

600~1200 |

||

|

Bonding strength (MPa) |

Dry bonding |

3.7~4.1 |

4.2~5.1 |

3.4~3.8 |

3.9~4.7 |

3.2~3.9 |

4.0~4.8 |

|

|

Wet bonding |

2.2~2.7 |

3.6~4.3 |

2.1~2.4 |

3.1~4.1 |

2.1 ~2.4 |

2.0~2.3 |

||

|

Tensile strength (MPa) |

25~35 |

20~40 |

15-20 |

15~20 |

10~15 |

8-112 |

||

|

Compressive strength (MPa) |

55~70 |

70-90 |

50~65 |

70~80 |

55~70 |

55~65 |

||

|

Elongation at break (%) |

/ |

5~15 |

/ |

50~70 |

/ |

30~50 |

||

|

Toxicity (LD50) |

>5000 |

>5000 |

>5000 |

>5000 |

>5000 |

>5000 |

||

Figure 2 Typical Formulation and Properties of Eco-friendly Epoxy

Figure 3 Comparison Before and After Leakage Treatment in the Valve Chamber of the South-to-North Water Diversion P;roject East Main Canal

Figure 4 Comparison Before and After Leakage Treatment in the Lining of Headrace Tunnel of the Zhelin Hydropower Plant