Main Participants: Wang Yujie, Liu Lipeng, Duan Qingwei, Wang Xiaogang, Cao Ruilang, Zhang Qiang, Jiang Long, Zhao Yufei, Ling Yongyu, Pi Jin, Sun Ping, Lin Xingchao, Sun Xingsong, Xiao Haohan, Wang Zonglin

Technologies for identifying external water pressure and controlling seepage of the hydraulic tunnel liners in high-pressure and water-soaked strata has long been a major challenge for the construction of deep-lying tunnels. The accuracy of external water pressure and reasonable seepage control are not only directly related to the safety and cost-effectiveness of tunnel liners, but also affect the ecological security of the groundwater environment in construction site. Currently, designing the external water pressure of tunnels still relies on engineering-based analogies and experience, posing a huge risk to project construction, operation and eco-environmental safety. Our project team carried out a 10-year systematic study based on national, provincial, ministerial and major water projects, and have developed technologies for external water pressure identification and seepage control of hydraulic tunnel liners in high-pressure and water-rich strata, in a bid to handle the external water pressure on deep-lying tunnels.

· The technology for monitoring groundwater full-cycle evolution of the hydraulic tunnel and the method of locating the initial water head;

· The working mechanism of the external water pressure on hydraulic tunnel liner in high-pressure and water-rich strata, and the quantification of such external water pressure;

· Quantitative design of seepage control for hydraulic tunnels in high-pressure, water-rich strata and a new type of lining structure;

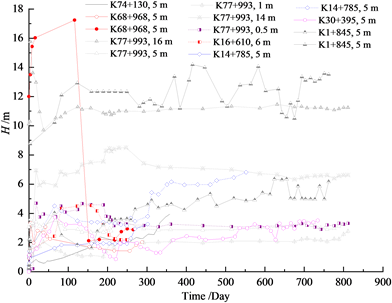

· Having created the technology for comprehensive monitoring of hydraulic connections among surrounding rock layers, surface deep holes and the inside tunnels, by discarding the misconception between the apparent water head and the initial water head; and proposed the method of identifying the initial water head based on the monitoring data of seepage field disturbance;

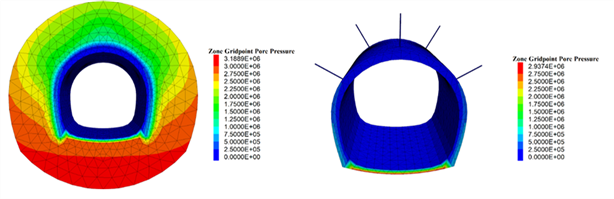

· Having revealed the distribution and evolution laws of the external water pressure in different strata and with different seepage control measures through modelling, numerical simulation and theoretical analysis, in response to the problem of great subjectivity in regulating external water pressure reduction coefficient values; and established a quantitative approach for determining external water pressure taking into account both geological and seepage control factors;

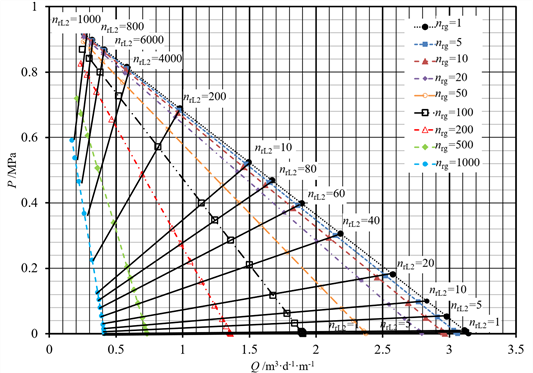

· Given the challenge of the seepage control design for deep-lying hydraulic tunnels in high-pressure and water-rich strata, having proposed the standards for allowable external water pressure and seepage control, and developed a pressure-flow relationship diagram and a quantitative method for seepage control designing, and invented a new composite liner structure to cope with the risk of asymmetrical pressure from traditional waterproofing and drainage measures.

The technologies have been applied to major projects such as the water diversion from the Hanjiang River to the Weihe River, the ABH project, the water diversion in central Yunnan and the Guangdong water resources allocation around the Beibu Gulf, solving the difficulties in tunnel designing, bringing about significant social, economic and environmental benefits. The technologies are expected to play a greater role in the construction of the national smart water grid.

![]()

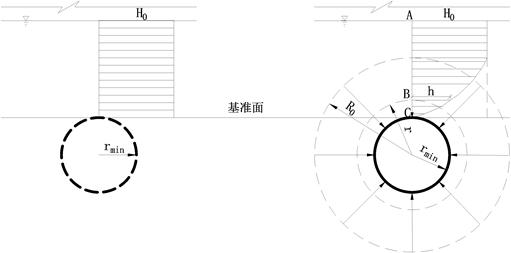

Fig.1 Distribution of water head in surrounding rock before and after tunnel excavation

Fig.2 Changes in underground water head in rock mass at a typical section

Fig.3 Relationship diagram between seepage flow and external water pressure on composite liners

Fig.4 The seepage field following tunnel excavation and waterproofing and drainage measures

Fig.5 The new

composite lining structure and the distribution of external water pressure on liners