Main Participants: ZHANG Guoxin, ZHU Bofang, LIU Yi, LIU Youzhi, ZHANG Lei, LI Songhui, QIU Yongrong, ZHOU Qiujing, WANG Zhenhong, ZHU Zhenyang, ZHANG Yan, XIN Jianda, JIN Xinxin, Lei Zhengqi, LUO Xiangyu, LIU Ruiqiang, LIU Yu, MA Xiaofang, LI Jintao

This technology belongs to the field of water conservancy and hydropower engineering, which is developed to solve the problems related to engineering safety and quality control. Crack prevention is an important task of concrete dam construction, and it is also one of the key points and challenges for construction control. Concrete cracking will affect the quality and durability of the project, and serious ones will even endanger the safety of the dam.

This project aims to solve the world-class problem of cracking prevention of high concrete dams. In view of the needs of temperature control for cracking prevention of high concrete dams and the shortcomings of existing researches, the research team has profoundly revealed the cracking mechanism of high concrete dams and improved the theory and method of temperature control for cracking prevention of high concrete dams by means of theoretical research, model testing, mechanism analysis, software development, field testing, system integration and application improvement in close combination with the construction and practice of high concrete dams; developed an efficient, large-scale finite element simulation software for temperature field and stress field which provide real-time simulation; as well as put forward the “9-3-1” overall solutions to prevent all kinds of cracks in high concrete dams, realizing the comprehensive intelligent control of the whole dam in whole process as well as the spatio-temporal temperature gradient and solving the chronic difficulty of “no dam without crack”.

· Having systematically revealed the law of temperature stress development and crack formation mechanism of high concrete dams and improved the theory of temperature control and crack prevention, which provides theoretical support for temperature control and cracking prevention of high concrete dams;

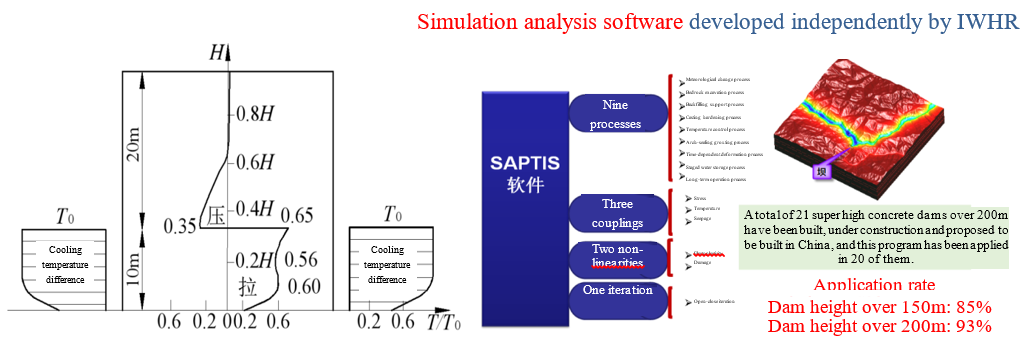

· Having proposed and integrated a variety of algorithms and mathematical models to describe the dam shape, material properties and changes in construction process, and developed a high-performance simulation analysis software for temperature stress of concrete dam, which realizes the simulation of temperature and stress field of the whole dam in the whole process from construction to operation, laying a solid foundation for dam performance simulation and safety evaluation;

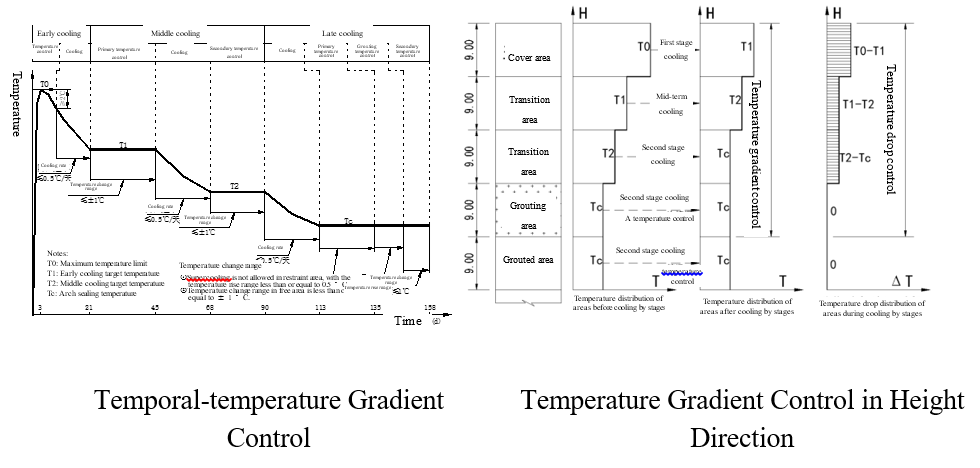

· Having put forward the “9-3-1” overall solutions to prevent all kinds of cracks in high concrete dams, which include the nine-word principle (early protection, small temperature difference and slow cooling process), the three-stage cooling (early, middle and late stage) and one temperature control (intelligent control). The relevant temperature control strategies and methods were included in the specifications such as Design Code for Temperature Control of Concrete Dam (NB/T35092-2017) and Technical Specification for Temperature Controlling of Hydraulic Concrete Construction (DL/T 5787-2019), which provide important technical support for the high-quality and efficient construction of high concrete dams in China.

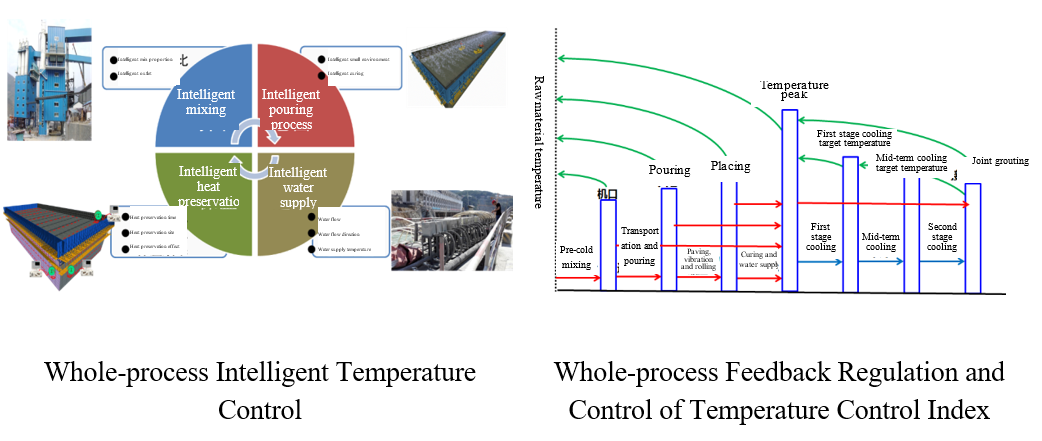

· Having presented a full-process intelligent temperature control methods and developed complete a set of equipment and software to realize the automatic acquisition, interconnection, real-time evaluation, real-time decision-making and intelligent control of the whole process from the outlet temperature, pouring temperature, placing temperature, highest temperature to the later temperature, providing important technical support for the effective guarantee of temperature control quality at the project site.

The complete set of theory and method as well as technology and standard of temperature control for cracking prevention of high concrete dam proposed in this project have been widely used in 53 (over 100 meters) high dams and super high arch dams built or under construction in recent years, such as Laxiwa, Jinping I, Xiluodu, Wudongde, Baihetan, Ludila, Zangmu, Fengman reconstruction, Huangdeng, Datengxia, Yangfanggou and other dams, with the total value of research contracts reaching 350 million yuan, which has strongly supported the high-quality construction of these projects, bringing about economic benefit of more than 3 billion yuan.

A total of 60 papers have been published, 15 invention patents, 11 utility model patents and 13 software copyrights have been obtained, three monographs and two specifications have been issued. The relevant norms, standards and methods will also better guide and guarantee the high-quality, safe and efficient construction of future projects, especially those in the western alpine region, bringing greater economic and social benefits. They are of great reference value for the future dam construction in countries along the Belt and Road and the development of dam construction technology in the world.

Fig. 1 Superposition Principle of Double Constraint Surfaces for Cooling of Foundation Constraint Area

Fig. 2 SAPTIS Simulation Analysis Software Functions

Fig. 3

Temperature Gradient Control Strategy in Time and Space Directions of Dam

Fig. 4 Intelligent Temperature Control System